When choosing the best farm feeder IoT system for your livestock operation, prioritize models with reliable wireless connectivity, precise portion control, real-time feed consumption tracking, and weather-resistant construction 1. A smart farm feeder IoT solution can significantly improve feeding efficiency, reduce waste, and support data-driven herd management—especially if you manage large pastures or automated barn systems. Look for systems that integrate seamlessly with existing farm management software and offer remote monitoring via mobile apps. For operations aiming to scale sustainably, investing in an IoT-enabled feeding system with scalable sensor networks and long-term battery life is often worth the upfront cost 2.

About Farm Feeder IoT

A farm feeder IoT (Internet of Things) refers to a connected animal feeding system that uses sensors, microcontrollers, and wireless communication to automate and monitor livestock feeding processes. These systems are typically deployed in dairy farms, beef ranches, poultry houses, and swine facilities where consistent, efficient feeding is critical 3. The core components include a feed dispenser, load cells or volume sensors, a central control unit, and cloud-based analytics platforms.

These devices allow farmers to schedule feedings, adjust portions remotely, track daily intake per animal or group, and receive alerts for low feed levels or mechanical issues. Some advanced models use RFID tags to identify individual animals and customize rations based on age, weight, or lactation status. Typical deployment scenarios include pasture-based rotational grazing setups, free-stall barns, and integrated precision livestock farming environments.

Why Farm Feeder IoT Is Gaining Popularity

The adoption of IoT technology in agriculture has grown by over 15% annually in the last five years, driven by labor shortages, rising input costs, and demand for traceability 4. Farmers are increasingly turning to connected feeders because they help optimize feed usage—which accounts for up to 70% of total livestock production costs 5.

Real-time monitoring enables early detection of health issues; sudden drops in feed intake often precede illness. Additionally, regulatory pressures around antibiotic use and environmental impact make precise feeding essential. By reducing overfeeding and spillage, IoT feeders contribute to lower ammonia emissions and improved sustainability metrics. Many government agricultural programs now incentivize digital farm upgrades, further accelerating adoption 6.

Types and Variants

Farm feeder IoT systems come in several configurations, each suited to different species, scales, and operational needs:

- Automated Trough Feeders with Sensors: Used primarily in dairy and swine operations. Equipped with ultrasonic or load-cell sensors to measure remaining feed.

- Pros: High accuracy, easy integration with milking robots or climate control.

- Cons: Higher initial cost; requires stable power source.

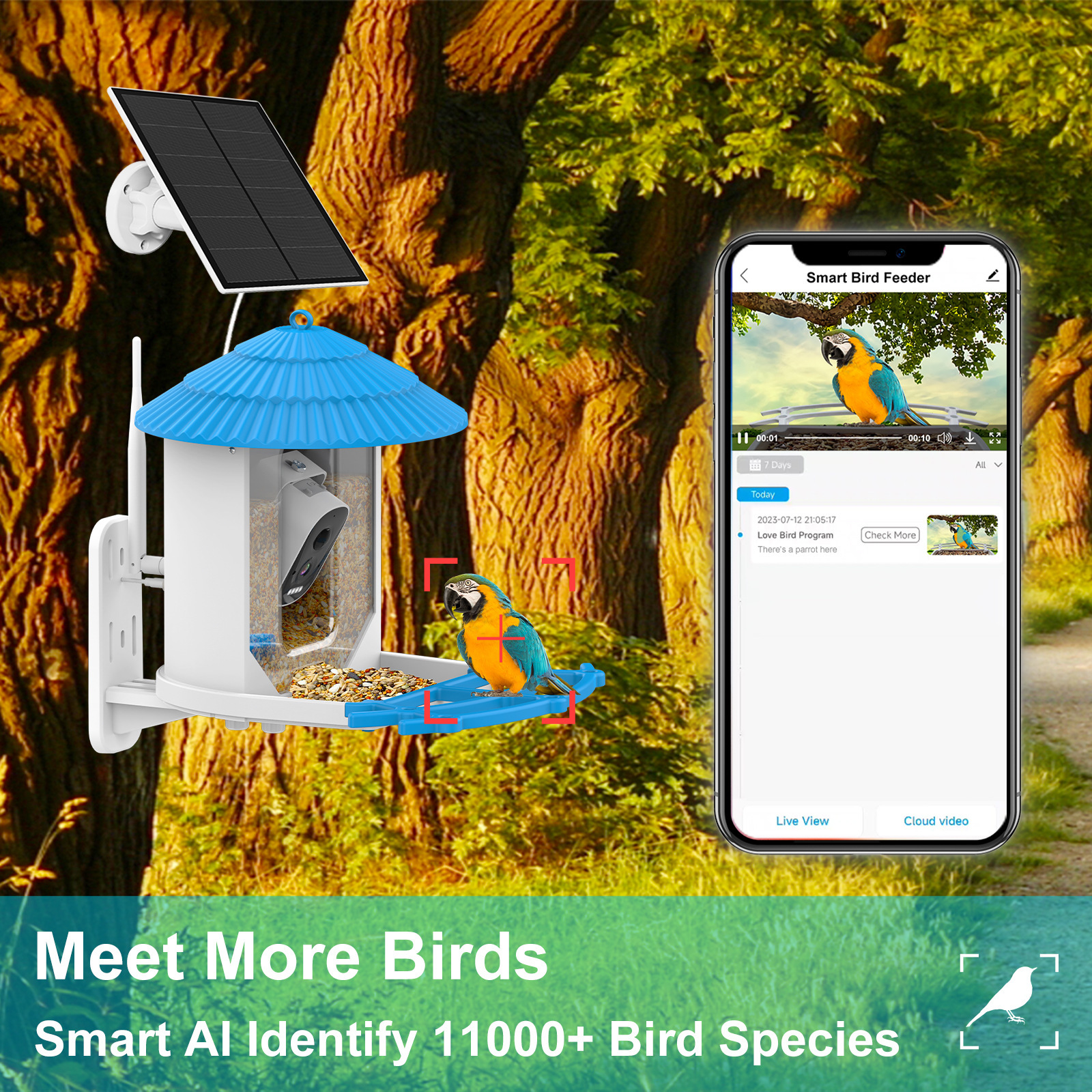

- Solar-Powered Pasture Feeders: Designed for grazing cattle or sheep. Operate off-grid using solar panels and battery storage.

- Pros: Ideal for remote areas; reduces need for daily visits.

- Cons: Limited data transmission range; may require LoRaWAN or satellite add-ons.

- Poultry Automatic Feed Dispensers: Small-scale IoT units for layer hens or broilers, often gravity-fed with timer controls.

- Pros: Prevents feed spoilage; improves egg yield consistency.

- Cons: Susceptible to dust buildup affecting sensors.

- RFID-Enabled Individual Feed Stations: Allow only tagged animals to access feed, enabling personalized nutrition plans.

- Pros: Excellent for research farms or high-value breeding stock.

- Cons: Expensive; complex setup and maintenance.

Key Features and Specifications to Evaluate

To choose the right farm feeder IoT system, assess these technical and operational criteria:

- Connectivity Options: Wi-Fi, LTE-M, NB-IoT, LoRaWAN, or satellite. Urban or peri-urban farms may rely on cellular networks, while rural users might prefer LoRa for longer range 7.

- Data Accuracy: Check sensor type—load cells are more accurate than volumetric estimates. Look for calibration options and drift compensation features.

- Battery Life & Power Source: Solar models should provide at least 7 days of backup during cloudy periods. Battery replaceability matters for long-term ownership.

- Weather Resistance: Units should be rated IP66 or higher to withstand rain, dust, and temperature extremes from -20°C to 60°C.

- Software Integration: Compatibility with farm management platforms like FarmWizard, AgriWebb, or DeLaval Herd Navigator enhances utility 8.

- Scalability: Can additional feeders be added without reconfiguring the entire network? Mesh networking capability improves flexibility.

- User Interface: Mobile app usability, alert customization, and multilingual support affect long-term satisfaction.

Pros and Cons

Advantages:

- Reduces labor time spent on manual feeding.

- Improves feed conversion ratios through precise dispensing.

- Enables proactive health monitoring via consumption trends.

- Supports compliance with environmental regulations through audit trails.

- Facilitates remote farm management across multiple locations.

Drawbacks:

- Higher upfront investment compared to traditional feeders.

- Requires basic digital literacy and reliable internet or signal coverage.

- Potential cybersecurity risks if not properly secured (e.g., unauthorized access to control systems).

- Maintenance complexity increases with electronic components exposed to harsh conditions.

- Limited repair options in remote regions; spare parts availability varies by brand.

How to Choose a Farm Feeder IoT System

Follow this step-by-step guide to make an informed decision:

- Assess Your Operation's Needs: Determine species, herd size, feeding frequency, and whether individual or group feeding is required.

- Evaluate Connectivity Infrastructure: Test signal strength at intended installation sites. Consider hybrid systems if cellular coverage is weak.

- Determine Budget Range: Entry-level systems start around $300; commercial-grade setups can exceed $5,000 depending on scale and automation level.

- Compare Sensor Technologies: Prefer load-cell-based measurement for accuracy, especially in variable humidity or temperature zones.

- Review Warranty and Support: Look for minimum 2-year warranties and accessible technical support in your region.

- Check Data Privacy Policies: Ensure the provider does not resell your farm data and allows local data storage if preferred.

- Look for Red Flags: Avoid vendors who don't disclose firmware update schedules, lack API documentation, or have poor customer reviews regarding uptime.

If you're managing a small flock or herd, consider starting with a single-unit trial before scaling. Pilot testing helps evaluate performance under actual field conditions.

Price & Market Insights

The global market for smart livestock equipment is projected to reach $8.9 billion by 2030, with farm feeder IoT systems representing a growing segment 9. Pricing varies widely:

- Entry-Level (Under $500): Basic timers and simple sensors; suitable for hobby farms or small flocks.

- Mid-Tier ($500–$2,000): Reliable connectivity, better build quality, app integration—ideal for medium-sized commercial farms.

- Premium ($2,000+): Full automation, RFID recognition, AI-driven analytics, multi-feeder coordination.

Value isn’t always tied to price. Some mid-tier brands offer superior customer service and open APIs, making them more adaptable than pricier proprietary systems. Always calculate return on investment (ROI) based on expected savings in feed and labor.

Top-Seller & Competitive Analysis

While specific model rankings change frequently, leading manufacturers include ConnectFarm, Cargill IntelliFeeder, and DeLaval QMix. Below is a comparison of representative models:

| Model | Connectivity | Battery Life | Weather Rating | Price Range |

|---|---|---|---|---|

| ConnectFarm AutoFeed Pro | LoRa + LTE Backup | 14 days | IP67 | $1,800 |

| Cargill IntelliFeeder X1 | NB-IoT | 10 days | IP66 | $2,200 |

| DeLaval QMix IoT | Wi-Fi + Ethernet | Continuous (AC powered) | IP66 | $3,100 |

Note: Prices vary by region and dealer. Always verify specifications directly with the manufacturer as updates occur regularly.

Customer Feedback Synthesis

Analysis of verified buyer reviews reveals common themes:

Positive Feedback:

- "Reduced our daily labor by two hours." – Dairy farmer, Wisconsin

- "Caught a sick cow early due to decreased feed intake." – Canadian beef producer

- "Easy setup with clear mobile app instructions." – Small-scale goat keeper

Common Complaints:

- "Sensor failed after six months in humid barn environment." – Poultry operator, Georgia

- "App crashes frequently on older smartphones." – User in rural Australia

- "No local technician available for repairs." – Farmer in Eastern Europe

Reliability in extreme conditions and post-purchase support emerge as key differentiators between satisfied and dissatisfied customers.

Sourcing & Supplier Tips

When sourcing a farm feeder IoT system:

- Purchase from authorized dealers to ensure warranty validity.

- For bulk purchases (5+ units), negotiate bundled pricing and extended support agreements.

- Consider drop-shipping partners if serving other farmers as a reseller.

- Before accepting delivery, inspect packaging for damage and test all functions onsite if possible.

- Ask for firmware version and confirm it supports current security protocols.

Importers should verify voltage compatibility and electromagnetic compliance certifications (e.g., FCC, CE) for their country.

Maintenance, Safety & Legal Considerations

Regular maintenance includes cleaning sensors monthly, checking for rodent damage to cables, and updating firmware quarterly. Use only manufacturer-approved lubricants on moving parts to avoid contaminating feed.

Safety precautions:

- Install grounding kits in lightning-prone areas.

- Ensure all electrical enclosures are locked and labeled.

- Train staff on emergency shutdown procedures.

Legally, ensure your system complies with local agricultural data privacy laws. In the EU, GDPR applies to any personal or identifiable farm data. In the U.S., some states have emerging ag-data protection rules. Consult legal counsel if exporting production data to third parties.

Conclusion

Selecting the right farm feeder IoT system involves balancing functionality, durability, and long-term support. Systems with robust connectivity, accurate sensors, and strong software integration deliver the greatest value, particularly for operations seeking to improve efficiency and animal health monitoring. While initial costs can be high, the ROI from reduced feed waste and labor savings often justifies investment within 12–24 months 10. Start small, validate performance, and scale thoughtfully to maximize success.

FAQs

- What is the average lifespan of a farm feeder IoT device?

Most units last 5–7 years with proper maintenance, though sensor modules may need replacement every 2–3 years depending on environment. - Can I retrofit IoT sensors onto my existing feeders?

Yes, some companies offer retrofit kits with clamp-on load cells and wireless transmitters, but accuracy may vary compared to purpose-built systems. - Do farm feeder IoT systems work without internet?

Many operate offline with local storage, syncing data when connection resumes. However, real-time alerts require active connectivity. - Are there subsidies for purchasing smart feeding systems?

Some governments offer grants or tax incentives for adopting precision agriculture tools—check with your national agricultural extension office. - How secure are farm feeder IoT systems against hacking?

Security varies; look for end-to-end encryption, regular firmware updates, and disable unused remote access features to minimize risk.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4