When choosing IoT solutions for poultry farming, prioritize systems that offer real-time environmental monitoring, automated climate control, feed/water tracking, and seamless integration with mobile alerts. The best options combine sensor accuracy, durability in high-humidity coops, and scalable cloud platforms—ensuring you maintain optimal bird health while reducing labor costs and improving yield predictability 1. For most mid-sized to large operations, modular wireless sensor networks with remote access deliver the strongest return on investment.

About IoT Solutions for Poultry

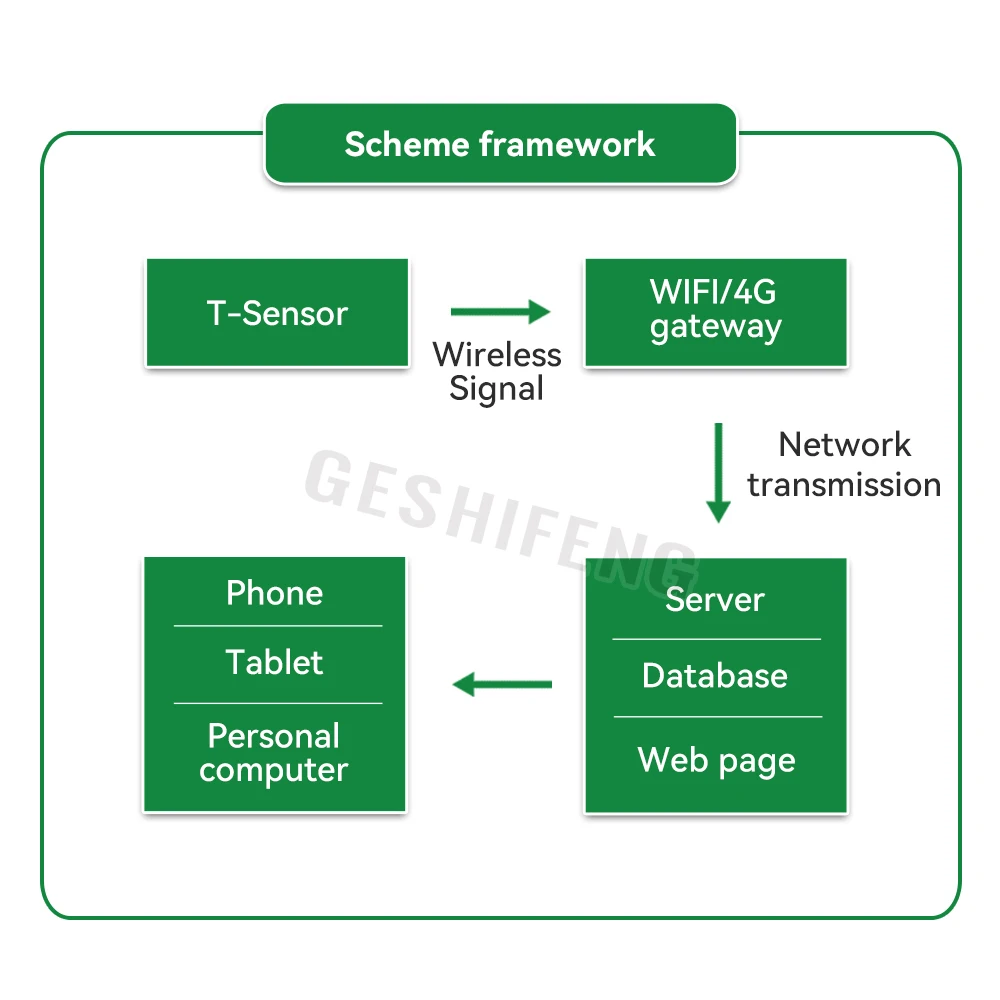

IoT (Internet of Things) solutions for poultry refer to interconnected devices and software platforms designed to monitor, manage, and optimize conditions within poultry farms. These systems typically include sensors for temperature, humidity, ammonia levels, lighting, ventilation, feed consumption, and water usage—all transmitting data wirelessly to a central dashboard accessible via smartphones or computers 2.

Common use cases involve automating barn environments to prevent heat stress or respiratory issues in birds, tracking growth patterns through feeding behavior, and receiving instant alerts when anomalies occur—such as power outages or equipment failure. Some advanced setups integrate AI-driven analytics to forecast disease risks or recommend adjustments based on historical performance.

Why IoT Solutions for Poultry Are Gaining Popularity

The global shift toward precision agriculture has accelerated adoption of smart IoT solutions for poultry management. Rising labor costs, stricter biosecurity regulations, and increasing consumer demand for traceable, ethically raised meat are driving farmers to adopt digital tools 3.

Additionally, climate volatility makes manual monitoring insufficient. IoT enables proactive intervention by detecting subtle changes before they impact flock health. Studies show farms using connected monitoring systems report up to 15% lower mortality rates and improved feed conversion ratios (FCR), directly boosting profitability 4.

Types and Variants of IoT Solutions for Poultry

1. Standalone Sensor Kits

These are entry-level packages consisting of individual sensors (e.g., temp/humidity) linked to a local gateway. Data is often viewable via an app but may lack automation features.

- Pros: Low upfront cost, easy setup, suitable for small farms.

- Cons: Limited scalability, minimal integration with existing farm machinery, no predictive analytics.

2. Integrated Climate Control Systems

Full-featured systems that not only monitor but also automatically adjust heaters, fans, misters, and lights based on preset thresholds.

- Pros: High level of automation, reduces human error, improves consistency in growing conditions.

- Cons: Higher initial investment, requires technical knowledge for configuration, potential downtime if internet fails.

3. Feed and Water Monitoring Networks

Dedicated IoT tools that track daily intake per pen, detect blockages or leaks, and correlate consumption with weight gain.

- Pros: Enables precise nutrition planning, early detection of illness (via reduced appetite), supports better inventory forecasting.

- Cons: Sensors can be sensitive to debris; calibration needed regularly; works best when combined with other monitoring layers.

4. End-to-End Farm Management Platforms

Enterprise-grade solutions offering centralized dashboards that aggregate data from multiple sources—environmental sensors, RFID tags, feed logs, veterinary records, etc.

- Pros: Comprehensive oversight, supports compliance reporting, integrates with ERP or accounting software.

- Cons: Expensive, longer implementation time, may require staff training or dedicated IT support.

Key Features and Specifications to Evaluate

Accuracy and Calibration

Sensor precision is critical. Look for temperature sensors with ±0.5°C accuracy and humidity sensors rated at ±3% RH. Ammonia detectors should have detection ranges between 0–100 ppm with clear alarm thresholds 5. Check whether recalibration is required annually or more frequently.

Connectivity Options

Wi-Fi works well for smaller barns near routers, but larger farms benefit from LoRaWAN, NB-IoT, or cellular-based transmission due to greater range and reliability in rural areas 6. Ensure the system supports offline data logging during network outages.

Data Access & User Interface

A responsive mobile app or web portal should allow real-time viewing, customizable alerts (SMS/email/push), and exportable reports. Consider ease of use for non-tech-savvy workers.

Power Requirements

Battery-powered sensors offer flexibility but need replacement every 6–12 months. Solar-assisted units reduce maintenance but cost more. Hardwired systems are reliable but limit placement options.

Scalability and Integration

Choose platforms that support adding new sensors without replacing the entire hub. Compatibility with third-party systems (like feeders or egg collectors) increases long-term value.

Pros and Cons: When to Invest in IoT for Poultry

Advantages

- Improved animal welfare: Continuous monitoring prevents extreme conditions that harm birds.

- Labor savings: Automation reduces routine checks, freeing staff for higher-value tasks.

- Better decision-making: Historical data helps refine feeding schedules, vaccination timing, and stocking density.

- Regulatory compliance: Digital logs assist in meeting food safety and audit requirements.

Limitations

- Initial complexity: Setup may require professional installation or IT assistance.

- Ongoing costs: Subscription fees for cloud storage or premium analytics can add up.

- Cybersecurity risks: Connected systems must be protected against unauthorized access.

- Not ideal for very small flocks: ROI diminishes under ~5,000 birds unless part of a broader tech upgrade.

How to Choose IoT Solutions for Poultry: Step-by-Step Guide

- Assess Your Farm’s Needs: Identify pain points—are you struggling with ventilation control, high chick mortality, or inconsistent feed usage? Match these to specific IoT capabilities.

- Determine Scale: Smallholders (<5k birds) may start with standalone kits. Commercial farms (>10k birds) should consider integrated or enterprise systems.

- Evaluate Connectivity Infrastructure: Test signal strength across sheds. If Wi-Fi is weak, explore LoRa or cellular alternatives.

- Review Sensor Placement Requirements: Avoid placing humidity sensors near water lines or ammonia detectors close to manure pits where readings skew.

- Check Vendor Support: Prioritize companies offering installation help, training, and responsive customer service.

- Verify Data Ownership and Privacy Policy: Confirm you retain full rights to your farm data and understand how it's stored or shared.

- Look for Red Flags: Be cautious of vendors who don’t disclose sensor specs, lack user reviews, or lock you into proprietary hardware with no exit strategy.

Price & Market Insights

Pricing varies widely:

- Entry-level kits: $200–$600 (basic temp/humidity/light monitoring).

- Mid-tier systems: $1,000–$3,000 (climate control + feed tracking + mobile alerts).

- Premium/enterprise platforms: $5,000+ (multi-barn coverage, AI analytics, API integrations).

Subscription fees range from $20–$100/month depending on data volume and feature access 7. While cheaper systems seem appealing, frequent malfunctions or poor support can lead to higher long-term costs. Focus on total cost of ownership over five years—including maintenance, battery replacements, and software updates.

| Model Type | Starting Price | Key Features | Best For |

|---|---|---|---|

| X-Agro Poultry Monitor | $499 | Temp, humidity, light sensing; mobile alerts | Small farms, backyard producers |

| SmartFarm ProClimate | $2,200 | Auto-ventilation, ammonia detection, cloud sync | Commercial broiler farms |

| AviSync Enterprise | $7,500 | AI analytics, RFID integration, multi-site dashboard | Large integrators, contract growers |

Customer Feedback Synthesis

Analysis of verified buyer reviews reveals consistent themes:

- Positive feedback: Users praise timely alerts that prevented heat-related losses, intuitive apps, and measurable drops in feed waste. Many note improved audit readiness due to automatic recordkeeping.

- Common complaints: Poor customer support after purchase, unexpected subscription hikes, and sensor drift over time (especially in dusty environments). Some users reported difficulty integrating new systems with legacy ventilation controllers.

To mitigate risks, read independent forums and request trial periods before committing.

Sourcing & Supplier Tips

Buy from suppliers with proven experience in agricultural IoT—not general electronics retailers. Reputable vendors often partner with universities or extension services for field testing.

- For bulk purchases (e.g., coop-wide deployment), negotiate bundled pricing or extended warranties.

- If considering white-label reselling, confirm licensing terms and branding permissions.

- Before accepting delivery, inspect packaging integrity and test each sensor against known standards (e.g., calibrated thermometer).

- Ask about firmware update policies—regular patches ensure security and functionality improvements.

Maintenance, Safety & Legal Considerations

Regularly clean sensor housings to prevent dust or condensation buildup. Replace batteries proactively and back up critical data monthly.

Safety-wise, ensure all electrical components meet IP66 or higher ratings for dust and moisture resistance. Install grounding rods if using outdoor gateways.

Legally, comply with local data protection laws (e.g., GDPR in Europe). In some regions, automated systems used in certified organic operations must be documented and approved by certifying bodies. Always verify regulatory alignment before full rollout.

Conclusion

Selecting the right IoT solution for poultry farming depends on your operation's size, goals, and technical capacity. Start by identifying key challenges, then match them to systems offering accurate sensing, reliable connectivity, and actionable insights. While initial costs exist, the long-term benefits—improved bird health, reduced losses, and streamlined management—make IoT a worthwhile investment for modern poultry producers. Prioritize vendors with transparency, strong support, and scalable designs to future-proof your farm.

FAQs

Q: What is the most important sensor in an IoT poultry system?

A: Temperature and humidity sensors are foundational, as thermal stress significantly impacts growth and survival rates.

Q: Can I install an IoT system myself?

A: Yes, many entry-level kits are DIY-friendly, but complex integrations (e.g., linking to ventilation motors) may require technician assistance.

Q: Do IoT systems work during internet outages?

A: Most store data locally and resume syncing once connection is restored, though real-time alerts may be delayed.

Q: How often do sensors need calibration?

A: Typically once per year, but consult manufacturer guidelines—some electrochemical sensors degrade faster in harsh conditions.

Q: Are there government grants for adopting smart farming tech?

A: Some countries offer subsidies or low-interest loans for agri-tech upgrades; check with your national agricultural department for programs.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4