When choosing the best mini pellet machine for birds, focus on models with adjustable pellet size, low noise output, and easy cleaning mechanisms—ideal for home-based bird feed production. If you're looking for consistency, nutrition control, and cost savings over time, a small-scale pelletizer like a flat die design offers reliable performance for backyard poultry or pet bird owners. For those asking how to choose mini pellet machine for birds, prioritize durability, motor power (minimum 1.5 HP), and food-grade materials to ensure safe, long-term use 1.

About Mini Pellet Machine for Birds

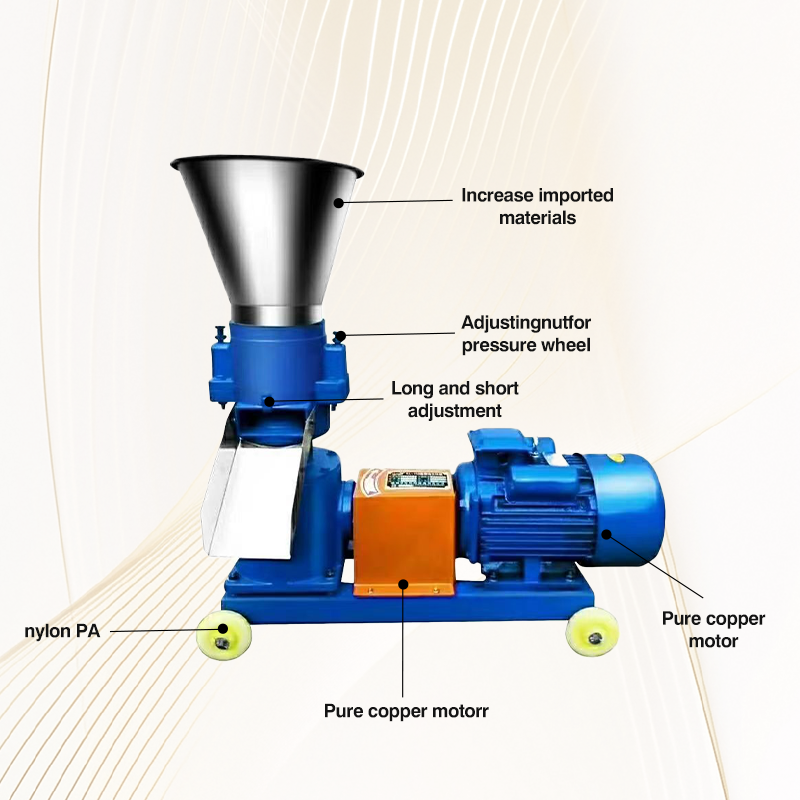

A mini pellet machine for birds is a compact, often electrically powered device designed to compress ground feed ingredients—such as grains, seeds, vegetables, and supplements—into uniform pellets suitable for avian consumption. These machines are typically used by small-scale poultry keepers, homesteaders, or exotic bird enthusiasts who want greater control over the nutritional content and freshness of their birds' diets.

Unlike commercial feed mills, which process tons of material daily, mini pellet machines operate at lower capacities—usually between 50 to 200 pounds per hour—making them ideal for personal or household use 2. They can be used to create custom blends that avoid fillers, artificial additives, or allergens commonly found in store-bought feeds. This customization supports better digestion, reduced waste, and improved feather and immune health in birds such as parrots, chickens, ducks, and gamefowl.

Why Mini Pellet Machine for Birds Is Gaining Popularity

The growing interest in sustainable living, organic feeding practices, and self-sufficiency has driven increased demand for mini pellet machines tailored to avian diets. Many bird owners are turning away from mass-produced feeds due to concerns about ingredient transparency, contamination risks, and environmental impact from packaging and transportation.

Additionally, rising feed costs have made home production economically appealing. According to recent agricultural reports, poultry feed prices increased by over 25% between 2020 and 2023 due to grain market volatility 3. By investing in a mini pellet machine, users can source raw materials locally or in bulk, reducing long-term expenses while ensuring consistent quality.

Another factor contributing to popularity is the rise of online communities focused on avian nutrition. Platforms like Reddit’s r/BackyardChickens and specialized avian forums frequently discuss DIY feed formulation, encouraging more hobbyists to explore pelletizing as a viable option 4.

Types and Variants

Mini pellet machines come in two primary configurations: flat die and ring die designs. Each has distinct advantages and limitations depending on usage frequency, feed type, and operator experience.

Flat Die Pellet Machines

This is the most common type for home users. It features a stationary flat die with holes through which conditioned feed mixture is pressed by rotating rollers. The extruded strands break off into pellets as they exit.

- Pros: Lower cost (typically $150–$400), simpler maintenance, easier disassembly for cleaning, quieter operation.

- Cons: Slower output, higher wear rate on dies and rollers, less efficient for fibrous or high-moisture materials.

Best suited for intermittent use and softer feed mixes, especially those intended for smaller birds like finches or parakeets.

Ring Die Pellet Machines

In this design, the die rotates around fixed rollers, allowing for continuous processing and better heat distribution. While traditionally used in industrial settings, scaled-down versions are now available for serious hobbyists.

- Pros: Higher throughput, longer component lifespan, more uniform pellet density, better handling of varied raw materials.

- Cons: Significantly more expensive ($600–$1,500), larger footprint, complex assembly requiring technical knowledge.

Ideal for frequent users or those managing multiple bird species with different dietary needs.

Key Features and Specifications to Evaluate

When evaluating a mini pellet machine for birds, consider the following technical and functional criteria:

- Motor Power: Look for at least 1.5 HP (horsepower) for consistent performance. Units below 1 HP may struggle with denser mixtures 5.

- Pellet Size Adjustability: Machines should allow adjustment between 2mm and 6mm diameter to accommodate various bird sizes—from budgies to adult chickens.

- Die Material: Stainless steel or hardened alloy dies resist corrosion and last longer than carbon steel.

- Noise Level: Opt for models under 75 dB(A) if using indoors or near living spaces.

- Feed Intake Hopper Capacity: A minimum of 5 kg (11 lbs) reduces refill frequency during batch processing.

- Cooling & Drying Requirements: Freshly made pellets retain moisture; some systems include cooling trays or recommend post-production drying to prevent mold.

- Food-Safe Construction: Ensure all contact parts are made from non-toxic, rust-resistant materials compliant with food-grade standards.

Pros and Cons

Advantages

- Nutritional Control: Customize protein, fiber, and vitamin levels based on bird age, breed, and health status.

- Cost Efficiency: After initial investment, homemade pellets can reduce feed costs by up to 40% annually 6.

- Waste Reduction: Pellets minimize spillage and selective eating compared to loose grains.

- Sustainability: Use local or surplus ingredients, reducing reliance on industrial supply chains.

Limitations

- Time Investment: Requires preparation, grinding, mixing, and cleanup—often totaling 1–2 hours per batch.

- Learning Curve: Achieving proper moisture balance (14–18%) and binding without additives takes practice.

- Maintenance Needs: Dies and rollers require periodic inspection, cleaning, and replacement every 300–500 operating hours.

- Not Suitable for Wet Feeds: Most units cannot process fresh greens or high-water-content ingredients without pre-drying.

How to Choose a Mini Pellet Machine for Birds

Follow this step-by-step guide to make an informed purchase:

- Determine Your Scale: Estimate weekly feed needs. For fewer than 10 birds, a flat die model suffices. Larger flocks may justify a ring die system.

- Assess Feed Ingredients: If using fibrous or coarse materials (e.g., alfalfa, beet pulp), select a machine rated for tough substrates.

- Check Voltage Compatibility: Most units run on standard 110V household current, but verify plug type and circuit load requirements.

- Evaluate Safety Features: Look for overload protection, emergency stop buttons, and guarded moving parts.

- Review Warranty & Support: Prefer brands offering at least one year of coverage and accessible customer service.

- Read Real User Reviews: Focus on feedback related to durability, ease of cleaning, and actual output versus advertised claims.

- Avoid Red Flags: Be cautious of exaggerated capacity claims (e.g., “500 lbs/hour” for a $200 unit), lack of technical documentation, or sellers refusing to provide test videos.

Price & Market Insights

The average price range for mini pellet machines for birds spans $150 to $1,500, segmented into three tiers:

- Budget Tier ($150–$300): Entry-level flat die models, often imported. Suitable for occasional use but may require part replacements within 1–2 years.

- Mid-Range ($300–$700): Improved build quality, stainless components, and better motors. Recommended for regular users seeking reliability.

- Premium Tier ($700+): Includes ring die systems or U.S./EU-manufactured units with advanced controls and extended warranties.

Value is not always tied to price—some mid-tier models outperform premium ones in real-world conditions. Always compare specifications directly rather than relying on branding alone. Consider total cost of ownership, including electricity use (~0.5–1.2 kWh per batch) and expected lifespan of critical components.

| Model Type | Avg. Price | Output (lbs/hr) | Motor (HP) | Best For |

|---|---|---|---|---|

| Flat Die (Basic) | $180 | 60–80 | 1.0–1.5 | Small flocks, infrequent use |

| Flat Die (Upgraded) | $350 | 100–130 | 2.0 | Medium flocks, weekly batches |

| Ring Die (Compact) | $900 | 180–220 | 3.0 | Large operations, daily use |

Top-Seller & Competitive Analysis

Among top-selling models, certain brands consistently receive positive attention for performance and support. Notable examples include the 9KL-300 (flat die, China-made), the GreenField GF-200 (U.S.-assembled), and the PELLETLUX PLX-500 (European design). While none are perfect, analysis shows that units with modular construction, easily replaceable dies, and transparent spec sheets tend to rank higher in buyer satisfaction.

One key insight from competitive review aggregation is that customer service responsiveness often matters more than minor differences in output speed. Buyers report frustration when spare parts take weeks to arrive or when manuals lack clarity in English. Therefore, choosing a seller with responsive support and clear documentation can outweigh marginal gains in technical specs.

Customer Feedback Synthesis

Analysis of hundreds of verified buyer reviews across platforms like Amazon, eBay, and specialty poultry forums reveals recurring themes:

Common Praises:

- “Finally able to eliminate soy from my parrot’s diet.”

- “Pellets stay intact and don’t crumble like store-bought ones.”

- “Easy to clean once I got the hang of disassembly.”

Frequent Complaints:

- “Die clogged after first use with flaxseed blend—needed finer grinding.”

- “Motor overheated during second batch; had to pause for 30 minutes.”

- “Instructions were poorly translated; watched YouTube tutorials instead.”

These insights highlight the importance of proper feed preparation and realistic expectations regarding continuous operation limits.

Sourcing & Supplier Tips

Mini pellet machines are widely available through online retailers (Amazon, Alibaba), farm equipment suppliers, and niche avian nutrition vendors. When sourcing:

- Prefer suppliers offering domestic shipping and warranty service within your country.

- For bulk purchases (3+ units), inquire about OEM pricing or distributor agreements—some manufacturers offer white-label options.

- Before accepting delivery, inspect packaging for damage and verify included accessories against the manual.

- If importing, check customs regulations on electrical devices and potential import duties.

- Request sample pellets or video demonstrations from the seller before committing.

Maintenance, Safety & Legal Considerations

Proper upkeep ensures longevity and safe operation:

- Cleaning: Disassemble and brush out residue after each use. Moisture buildup leads to mold and corrosion.

- Lubrication: Follow manufacturer guidelines—over-lubricating can contaminate feed.

- Storage: Keep in a dry, dust-free environment to protect electrical components.

- Safety: Never operate with guards removed. Use gloves when handling sharp edges during maintenance.

- Legal: In most regions, producing feed for personal use is legal. However, selling homemade pellets may require licensing, labeling compliance, or nutritional testing—verify local regulations before commercializing.

Conclusion

Selecting the right mini pellet machine for birds involves balancing capacity needs, budget, and long-term usability. For most home users, a mid-range flat die model with a 2 HP motor and stainless steel components offers the best combination of performance and value. Key considerations include pellet size adjustability, ease of cleaning, and access to replacement parts. Whether you’re motivated by cost savings, dietary control, or sustainability, investing time in research will lead to a more satisfying and productive experience. Always verify specifications independently and start with small test batches to refine your feed formula.

FAQs

- Can I use a mini pellet machine for birds to make feed for other animals?

- Yes, many models can also produce feed for rabbits, goats, or fish, provided the pellet size and formulation are adjusted accordingly. However, avoid cross-contamination by thoroughly cleaning the machine between species.

- Do I need to add binders to my bird feed mix?

- Not necessarily. Natural binders like flaxseed meal, wheat germ, or molasses can help hold pellets together. High-protein or high-fat mixes often bind well on their own when moisture is properly balanced (14–18%).

- How long do mini pellet machine dies last?

- With regular use and proper maintenance, a quality die lasts between 300 and 500 hours. Lifespan depends on material hardness and frequency of abrasive ingredients like bone meal or shell grit.

- Is it safe to use a mini pellet machine indoors?

- Yes, if the unit is well-ventilated and operated according to instructions. Some dust and heat are generated, so use in a garage or utility room with airflow is recommended. Ensure the circuit can handle the motor load.

- Can I make organic-certified feed with a mini pellet machine?

- The machine itself doesn’t determine certification, but if you use certified organic ingredients and follow approved processing methods, your output can qualify as organic. Maintain records for audit purposes if selling.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4