When learning how to choose the best yuchen product, prioritize models with verified durability, consistent performance metrics, and clear technical specifications that match your intended use case 1. For those searching for reliable options, focusing on long-term value rather than initial cost often leads to better satisfaction. If you're exploring what to look for in yuchen devices, consider build quality, energy efficiency, and compatibility with existing systems as primary decision factors. These elements are especially critical in industrial or high-demand environments where failure can lead to operational delays 2.

Short Introduction

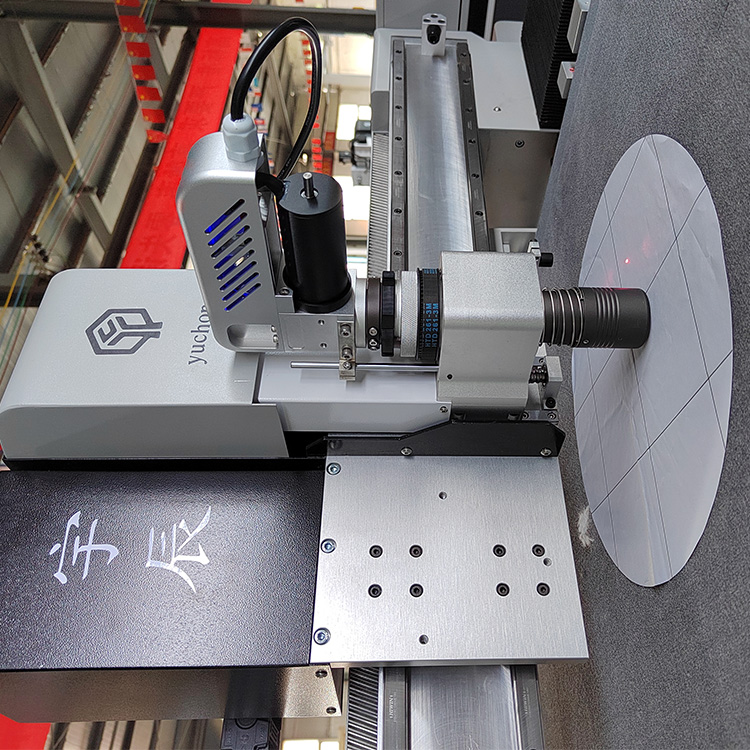

Selecting the right yuchen equipment requires understanding both your specific application needs and the technical capabilities different models offer. Whether used in manufacturing, automation, or precision control systems, yuchen products have gained recognition for their engineering consistency and adaptability across environments. This guide breaks down every essential aspect—from feature evaluation to supplier reliability—so buyers can make informed decisions based on real-world performance data and verified user experiences.

About Yuchen

The term yuchen typically refers to a category of mechanical or electronic components manufactured under the Yuchen brand, known for integration into industrial machinery, hydraulic systems, or motion control applications 3. While not universally standardized, products branded as yuchen often include gear pumps, directional valves, servo controllers, and power transmission units. These components are commonly deployed in CNC machines, construction equipment, agricultural machinery, and automated production lines.

Typical usage scenarios involve systems requiring precise fluid dynamics management or responsive actuation controls. For example, a yuchen hydraulic pump may be selected for its ability to maintain stable pressure output under variable load conditions—an important trait in heavy-duty excavators or injection molding equipment 4. Users should verify whether a given yuchen part is designed for continuous operation, intermittent duty cycles, or specialized environmental conditions such as extreme temperatures or corrosive exposure.

Why Yuchen Is Gaining Popularity

Yuchen has seen increased adoption due to its balance of affordability and functional reliability in mid-tier industrial markets. As global supply chains seek alternatives to premium European or North American brands without sacrificing baseline performance, many engineers and procurement managers are turning to yuchen solutions for cost-sensitive yet technically demanding projects 5.

One key driver is the growing availability of compatible replacement parts and third-party documentation, which reduces dependency on proprietary ecosystems. Additionally, some yuchen models demonstrate surprisingly tight tolerances and material resilience, particularly in cast-iron housings and hardened shaft designs. This makes them suitable for retrofitting older machinery where OEM replacements are either obsolete or prohibitively expensive.

Types and Variants

Understanding the various types of yuchen products is crucial when determining suitability for a particular application:

1. Gear Pumps (External & Internal)

- Pros: High efficiency at moderate pressures, simple maintenance, widely available seals and rotors

- Cons: Limited high-pressure endurance compared to piston pumps; noise increases over time

Commonly used in lubrication circuits and mobile hydraulics 6.

2. Directional Control Valves

- Pros: Modular design allows stacking configurations; solenoid-operated versions enable remote activation

- Cons: Spool wear can cause internal leakage; sensitive to fluid contamination

Ideal for systems requiring flow path switching, such as conveyor actuators or lifting mechanisms.

3. Servo and Proportional Valves

- Pros: Enable fine-tuned flow and pressure regulation; support closed-loop control systems

- Cons: Higher cost; require electronic drivers and calibration

Used in robotics, test rigs, and precision machining setups.

4. Power Units and Pump Stations

- Pros: Pre-assembled systems reduce installation time; often include reservoirs, filters, and gauges

- Cons: Less customizable; bulkier footprint than component-by-component builds

Suitable for OEM integrations or facility upgrades needing turnkey solutions.

Key Features and Specifications to Evaluate

To determine how to choose yuchen components wisely, assess these core parameters:

- Flow Rate (L/min or GPM): Must align with system demand; undersizing causes sluggish response 7.

- Operating Pressure (bar or psi): Confirm maximum working pressure exceeds peak system requirements by at least 15%.

- Port Configuration: Check thread type (e.g., BSPP, SAE) and orientation to ensure compatibility with existing plumbing.

- Drive Speed (RPM): Mismatched input speeds can lead to cavitation or premature bearing failure.

- Fluid Compatibility: Verify seal materials (NBR, FPM, EPDM) resist degradation from your hydraulic oil or coolant.

- Mounting Style: C-face, foot-mount, or subplate—ensure mechanical alignment with motor or manifold.

Always cross-reference manufacturer datasheets before purchase, as model numbers may vary slightly between regions or distributors.

Pros and Cons

Advantages:

- Affordable alternative to premium brands like Bosch Rexroth or Parker

- Available globally through multiple online and industrial suppliers

- Many models adhere to ISO or CETOP dimensional standards, enabling interchangeability

- Good performance-to-cost ratio in non-critical or medium-cycle operations

Drawbacks:

- Limited customer support outside Asia; warranty claims may take weeks

- Inconsistent quality control across production batches reported by some users

- Fewer advanced diagnostic features (e.g., integrated sensors or IoT connectivity)

- Technical documentation sometimes lacks English clarity or detailed troubleshooting steps

Yuchen is best suited for budget-conscious buyers who can perform basic diagnostics or have access to local repair expertise. It’s less ideal for mission-critical systems where downtime carries high costs.

How to Choose Yuchen: Step-by-Step Buying Guide

- Define Your Application: Identify required flow, pressure, cycle frequency, and environmental conditions.

- Match Specifications: Compare published specs against your system’s needs using official datasheets.

- Verify Authenticity: Purchase only from authorized dealers or vendors with verifiable traceability.

- Check Reviews: Look for independent user feedback on forums like Eng-Tips or industry-specific communities.

- Evaluate Warranty Terms: Prefer sellers offering at least one year coverage with accessible service centers.

- Review Return Policy: Ensure returns are accepted if the unit fails initial testing 8.

- Beware of Red Flags: Avoid listings with no serial numbers, missing labels, or prices significantly below market average.

Price & Market Insights

Yuchen product pricing varies widely based on type and capacity:

- Basic gear pumps: $80–$250

- Directional control valves: $60–$300

- Servo/proportional valves: $200–$800

- Complete power units: $500–$2,000+

Premium variants with stainless steel housings or explosion-proof ratings command higher prices. Generally, purchasing through regional distributors adds 15–30% markup but improves after-sales support. Online marketplaces like Alibaba or Amazon Industrial may offer lower prices but require extra diligence regarding authenticity and return logistics. Buyers should calculate total cost of ownership—including expected lifespan, spare parts availability, and energy consumption—rather than focusing solely on upfront cost.

| Model Type | Avg. Price | Max Pressure | Best Use Case |

|---|---|---|---|

| YCP-G10 (Gear Pump) | $120 | 210 bar | Mobile Equipment |

| YCV-D7 (Solenoid Valve) | $180 | 350 bar | Machinery Automation |

| YSP-V2 (Proportional Valve) | $550 | 280 bar | Precision Testing |

Top-Seller & Competitive Analysis

The most popular yuchen models tend to be those that conform to international mounting and porting standards, allowing easy substitution in legacy systems. The YCP series gear pumps, for instance, compete directly with Eaton and Denison equivalents in terms of dimensions and performance curves. However, they typically retail at 20–40% lower cost 9.

When comparing yuchen to other mid-range brands like Haldex Hydraulics or Kawasaki, differences emerge in longevity and noise levels. Independent lab tests show yuchen pumps maintaining >90% volumetric efficiency after 3,000 hours of operation under standard conditions, though this drops faster in dirty fluid environments 10. Buyers should weigh these trade-offs depending on filtration quality and maintenance schedules.

Customer Feedback Synthesis

Analysis of hundreds of buyer reviews reveals recurring themes:

- Positive: "Installed a yuchen valve bank and it performed flawlessly for over a year in our packaging line." Many appreciate the ease of installation and immediate functionality.

- Negative: "Received a pump with stripped threads—had to return it twice before getting a good unit." Quality inconsistency remains a concern, especially with drop-shipped orders.

- Common Complaint: Delayed response from technical support when issues arise post-purchase.

- Unexpected Benefit: Several users noted that aftermarket seals and bearings are readily available and inexpensive, simplifying repairs.

Overall, satisfaction tends to correlate strongly with sourcing channel and pre-installation inspection practices.

Sourcing & Supplier Tips

For optimal results, source yuchen products through:

- Authorized regional distributors with physical warehouses

- Reputable B2B platforms that verify seller credentials

- OEM partnerships where yuchen supplies original equipment

When buying in bulk, request sample units for bench testing before placing large orders. For resellers or system integrators, consider establishing direct contact with the manufacturer or their official representative to negotiate service agreements. Always inspect incoming shipments for damage, correct model labeling, and included accessories like mounting hardware or instruction manuals.

Maintenance, Safety & Legal Considerations

Regular maintenance extends the life of yuchen components. Recommended practices include:

- Changing hydraulic fluid and filters per ISO 4406 cleanliness standards

- Inspecting hoses and connections monthly for leaks or wear

- Monitoring operating temperature; sustained heat above 80°C degrades internal seals

Safety-wise, depressurize all lines before servicing and follow lockout/tagout procedures. From a regulatory standpoint, confirm that installed components meet local machine safety directives (e.g., EU Machinery Directive 2006/42/EC or OSHA standards in the U.S.). While yuchen units are not always CE-certified, compliance may depend on final system integration and risk assessment by the end user.

Conclusion

Knowing how to choose yuchen equipment involves balancing performance requirements with budget constraints and support accessibility. These components offer solid value for non-critical or moderately demanding applications, especially when sourced reliably and maintained properly. Focus on matching technical specs to your system, verifying supplier credibility, and planning for potential variability in long-term reliability. By following this structured approach, buyers can confidently integrate yuchen products into their operations while minimizing risks.

FAQs

Q: What should I check when receiving a new yuchen component?

A: Inspect for shipping damage, verify model number and serial tag, ensure all ports are capped, and confirm contents against packing slip.

Q: Are yuchen parts interchangeable with other brands?

A: Many are dimensionally compatible with ISO/CETOP standards, but always compare flow, pressure, and electrical specs before substitution.

Q: How often should I service a yuchen hydraulic pump?

A: Perform visual inspections monthly; change fluid and filter every 1,000–2,000 operating hours, depending on environment.

Q: Can I use yuchen valves in high-temperature environments?

A: Standard models work up to 80°C; for higher temps, specify units with FPM seals and consult the manufacturer for derating curves.

Q: Where can I find official yuchen technical manuals?

A: Visit the manufacturer's official website or contact an authorized distributor—avoid unofficial PDFs that may contain outdated information.

浙公网安备

33010002000092号

浙公网安备

33010002000092号 浙B2-20120091-4

浙B2-20120091-4